In modern factories, many tasks require workers to use their eyes intensively. Workers must have good eyesight and must concentrate on a certain workpiece or a certain point to complete. There are also many tasks that require workers to persist in using their eyes for a long time. Finished, even to work overtime to complete.

In some factories, night shift workers finish their work while others are resting, which is the most eye-consuming. Working under the above conditions, workers will quickly feel visual fatigue and have difficulty concentrating, which will affect work efficiency and even cause accidents due to mistakes.

Therefore, a comfortable and bright working environment is very important for factory workers. It can not only protect their eyes, relieve eye fatigue, but also improve work efficiency.

So how should the factory lighting design be broken?

First of all, the task of factory lighting is to ensure good visibility in the working environment, make work safer and more active, avoid accidents, reduce the number of failures and substandard products, and increase productivity.

Secondly, a good factory lighting design should have sufficient and uniform light in the working area, high luminous flux, suitable color temperature and reduce glare.

Next, we will elaborate on several aspects:

lighting method

1. Classification of lighting methods

There are three main ways of factory lighting: general lighting, partial lighting, and mixed lighting.

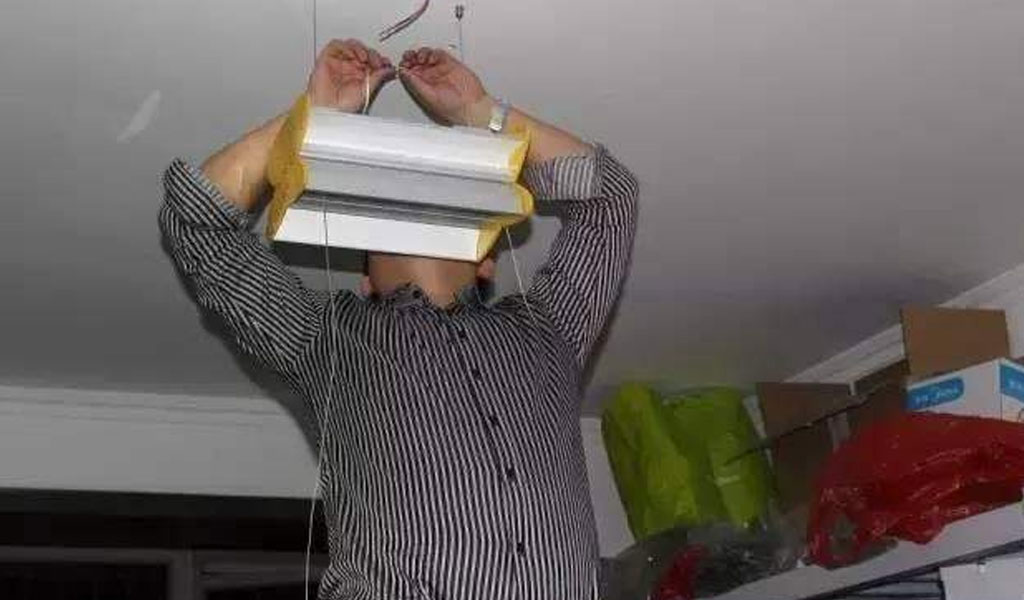

General lighting: also known as main lighting, it is generally placed on the top of the middle to provide overall lighting for the space, and the number is usually arranged according to the size of the factory.

Partial lighting: According to production needs, it is used in conjunction with general E27 Screw Household 200W Bulb Light, and lamps are placed to illuminate the working point at positions that require special accent lighting.

Mixed lighting: Generally used in large factories, the main lighting and local lighting are used to match each other to reduce light and dark areas and shadow areas.

2. Choice of lighting method

- (1) Mixed lighting should be used in places where the requirements for illumination are high and the density of working positions is not high, and it is unreasonable to use general lighting alone.

- (2) When the illumination requirements for the operation are not high, or due to the limitation of production technology conditions, it is not suitable to install local lighting, or it is unreasonable to use mixed lighting, it is advisable to use general lighting alone. A good factory lighting design has sufficient and uniform light in the working area, high luminous flux, suitable color temperature, and at the same time reduces glare. A comfortable working environment motivates employees to improve production and product quality.

- (3) When a certain work area requires higher than general lighting illuminance, partitioned general lighting can be used.

- (4) When the general lighting of the zone cannot meet the illumination requirements, local lighting should be added.

(5) Only partial lighting should not be installed in the work area.

However, when high-intensity gas discharge lamps are used as general High Power LED Bulb Light, the standard value of illuminance should not be lower than 50Lx in workplaces where people often work. For general lighting in mixed lighting, the illuminance value should be 5% to 15% of the illuminance value of the mixed lighting at this level, and the illuminance should not be lower than 30Lx. However, when using high-intensity gas discharge lamps, it should not be lower than 50Lx.

The choice of lamps

1. Types of lamps

The choice of factory lighting fixtures is directly related to the light intensity of the working environment and also directly affects work efficiency, so the choice of factory lighting fixtures is very important. At present, the commonly used lighting sources for factory workshop lighting mainly include metal halide lamps, electrodeless lamps and LED lamps.

Among them, LED lighting has the most promising prospect. We usually call factory workshop lighting fixtures factory lights or industrial and mining lights. Designing a reasonable lighting scheme and selecting appropriate lighting fixtures can not only save energy, but also greatly improve the work efficiency and comfort of workers. .

Then how to use the lamps depends on the height of the factory to determine the lamps and light sources to be used

Reasonable illumination

The lighting factors that affect vision in factory lighting mainly include illuminance level, brightness distribution, color appearance, light and shadow, light color, etc., but these factors have different influences on work efficiency, among which illuminance, that is, light effect, has the greatest impact on work efficiency .

The illuminance standard of general lighting for industrial buildings is also regulated by the country. For the working surface that needs to increase local lighting, the increased local lighting brightness value should be selected according to 1-3 times the general lighting illuminance value of the place. In addition, the specific Durable Honeycomb Fin High Bay Lights standards of various factories should also be designed in accordance with the regulations of relevant industries.

Standard value of illuminance on the working surface of the workplace:

2. The selection of enterprise lighting fixtures should follow the principles

- ①Convenient maintenance and safe use should be considered.

- ② In factories with explosive gas or dust, dustproof, waterproof or LED explosion-proof lights should be used. Control switches should not be installed in the same place, and explosion-proof switches should be used if they need to be installed in the same place.

- ③ For humid indoor and outdoor places, closed lamps with crystal water outlets or open lamps with waterproof ports should be selected.

- ④ Detachable LED Tunnel Lights should be used in hot and dusty places.

- ⑤ Sealed lamps should be used in rooms with corrosive gases and special humidity. All parts of lamps should be treated with anti-corrosion treatment, and switchgear should be equipped with protective devices.

- ⑥Indoors with dust, fully enclosed lamps should be used according to the amount and nature of the dust emitted.

- ⑦Lamps with protective nets should be used in factory buildings where lamps may be damaged by machinery; lamps with shockproof devices should be used in vibration places such as forging bells, air compressors, and bridge cranes.

A factory is a place for production and processing. The main purpose of industrial lighting is to increase productivity, ensure production safety, and form a comfortable visual environment. There is an inseparable relationship between lighting and work efficiency. Whether the lighting is good or not directly affects the entire production efficiency.

Therefore, when designing factory lighting illuminance, it is necessary to ensure a certain lighting level through reasonable E27/E40 Disk Fin LED Corn Lights calculations and lighting arrangements based on the corresponding lighting standards and actual site needs, so as to reduce the decline in productivity caused by insufficient lighting.

The Links From:How to cleverly design a comfortable factory lighting environment